1. Specification According to your requirement.

Material Stainless steel, brass, copper, aluminum, carbon steel, alloy steel etc.

Surface Treatment Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc.

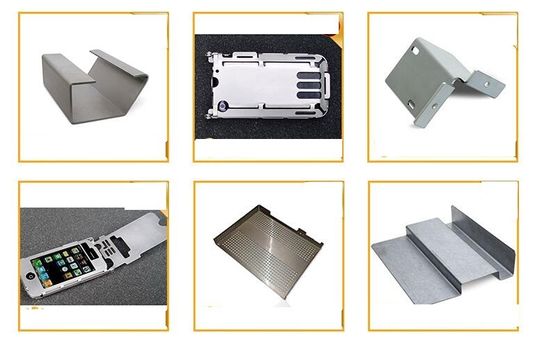

2. Applications Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment, light industry products, sanitation machinery, market/ hotel equipment supplies, artware etc.

Packaging Inner plastic bag, outer carton box, and we can also pack products according to your requirements.

3. Our features A company with industry and trade integration

Producing Equipment CNC machine SHENGYU & SYX42..Other machines including Spring machine Jinju & 502S, Shaft machine Liqiang,Auto lathes Libo & XB,Screw machine Hexing/SX & H series,Inclinable press machine WORLD & J23-80/ J23-65A/J23-16,Milling machine COYO/ALSGS & CY-L-90,Continuous hot wind tempering furnace Sanli & RJC210,Tapping machine Dongrong/EF,Grinder machine DA SHUANG YANG & 4. 4. M230-2, Lathe machine C6233 ,Wire cutting machine Deren & DK7740 etc.

Testing Equipment Projecting apparatus, Salt Spray Test, Durometer, and Coating thickness tester

Workforce A group of experienced production technician, sophisticated engineer and dedicated QC

About us Our company was founded in October, 2000, specializing in the production of CNC/AUTO lathe, springs, shafts, screws, stamping parts and other metal parts. Our main production modes are designing and proofing based on customers’ drawings or samples.

5. Main Markets North America, South America, Eastern Europe , West Europe , North Europe, South Europe, South Asia, Africa African

| Equipment |

CNC stamping/punching machine, CNC bending machine, CNC cutting

machine, 5~250 tons punching machines, welding machine, polish

machines... |

| Processed material |

stainless steel, copper, carbon steel (according to customer's

requirement) |

| Surface treatment |

Hot galvanized, polishing, chrome/zinc/nickel plating, powder coating,

anodize... |

| Making process |

Stamping, deep drawing,bending, punching, laster cutting,threading,

welding, tapping, riveting, grinding |

| Thickiness |

0.5mm ~12mm, or other special available |

| Inspection |

IQC, IPQC,FQC,QA |

| Certificate |

ISO 9001 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!